Solutions

Powering the pros to do more

Where OnSpec Robotics continue to create value

The applications for our adaptable robotic technology are seemingly endless. We have a long history of creating specialized solutions for remote challenges left previously unsolved. OnSpec Robotics have been employed for nuclear sample transportation, cross-border patrol, suspicious package reconnaissance, FPSO cleaning, tool recovery, wire installation, offshore painting, and so much more.

Nuclear Waste Sampling

Diving into the depths of nuclear remediation, where challenges abound and safety is paramount, we're confronted with the daunting task of managing radioactive waste. From contaminated soil to aging storage tanks, the hazards loom large. But fear not, for there's a beacon of hope on the horizon: Eddyfi Technologies nuclear waste sampling crawler. This cutting-edge solution is poised to revolutionize the remediation landscape. Read on to explore how this innovative crawler tackles the most hazardous environments, ensuring a safer and more efficient path towards managing nuclear waste. Learn more

Remote Cleaning

When America’s particle physics and accelerator laboratory, Fermilab, needed to remove 50 gallons of rock-hard grout from inside their Neutrino-Muon beamline, they sought an OnSpec Robot to get the obscure job done. The remote cleaning robot delivered an impressive 20,000 PSI jet of water to remove the grout said to have a compressive strength three times that of sidewalk concrete. Learn more

Implementing robotics to battle the inevitable biofouling that occurs on offshore structures brings a level of autonomy to a crew to maximize their time and budget. OnSpec Robotics have integrated a range of different cleaning mechanisms from heavy-duty brushes to cavijet sprayers to remove marine growth and other undesired coatings on both offshore and land-based assets. Learn more

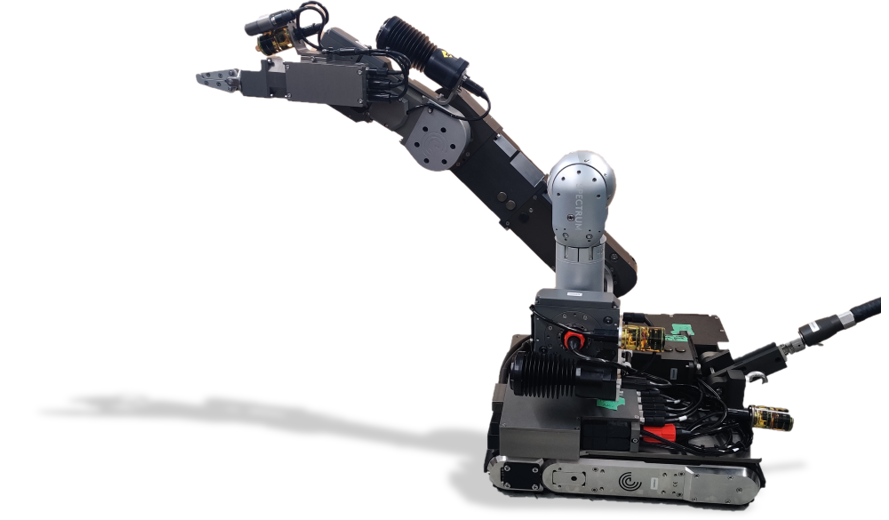

Marsupial Robotics

An OnSpec custom robot based on Eddyfi Technologies VersaTrax Y-Series vertical crawler with industrial transportation tracks was adapted to include a deployment tube for a third-party remotely operated vehicle, or ROV. The mobility and support solution for microROVs was responsible for transporting the inspection system through hundreds of feet of vent piping with a majority of vertical spans. The deployment mechanism utilized an electromagnet to hold the ROV in the tube while the TriTrax traversed the comprehensive vent lines. Learn more

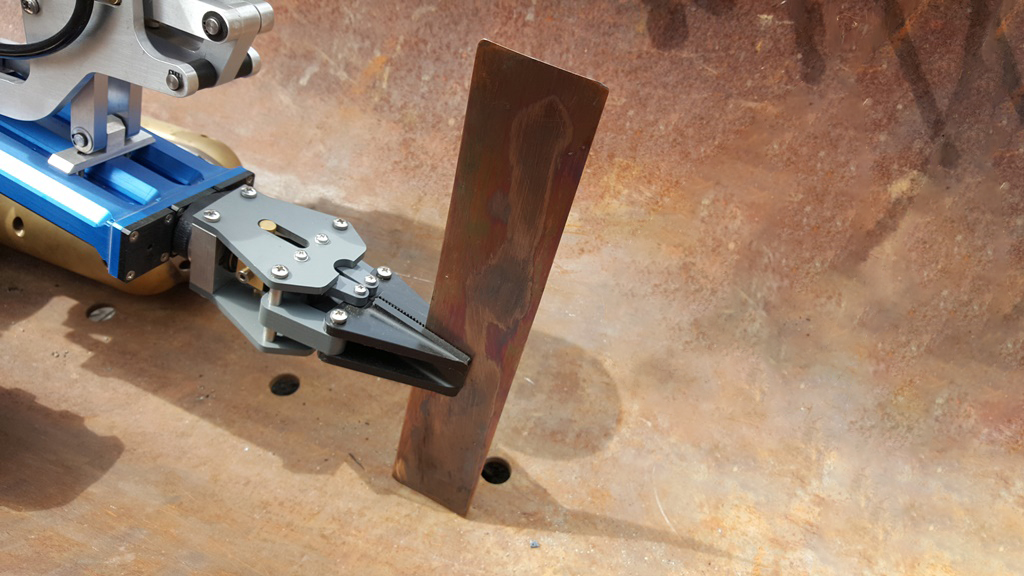

Foreign Object Search and Retrieval

For over 30 years, OnSpec Robotics have been deployed for remote recovery operations in response to anything from a dropped tool, a natural disaster, or even counterterrorism. When Pacific Gas and Electric, or PG&E, had an inspection tool return from a gas pipeline inspection missing some of its caliper parts, it sought OnSpec Robotics for a creative solution to retrieve them. A custom crawler was able to negotiate the constraints the pipeline presented and successfully recover what would have caused a problem and/or damage to a sensor tool run scheduled soon after. Learn more

X-Y Crawlers

One of the first XY crawlers designed and manufactured by Eddyfi Technologies was for Washington River Protection Solutions, or WRPS, for the tank inspection at The Hanford Site – a decommissioned nuclear production complex. In this case, the tight environment and capacity to position the inspection crawler were key reasons to use an XY crawler as the lack of space would make it impossible for a tethered crawler to rotate 180 degrees. The tether would get stuck between the inner and outer shell. The capacity to position and deploy a small robot in a tight air slot would have been extremely difficult for an operator to do without the lateral motion of an XY crawler. Learn more

Ready for robotics to help your business grow?

Our friendly and knowledgeable staff are committed to matching your precise needs with the exact robotic solution to ensure you minimize human and environmental risk and maximize production and cost efficiencies.